The yoga industry is growing fast. More people want yoga mats that match their health and environmental values. I recommend natural rubber yoga mats. They are the best choice for studios, retailers, and brands.

The global yoga mat market is changing fast. Consumers avoid PVC and synthetic materials. They want products that are safe for their bodies and good for the planet. This trend creates a huge opportunity. Businesses that source sustainable yoga equipment can benefit.

Studios report interesting feedback. Students ask about mat materials before buying. Retailers see green options outsell traditional mats by wide margins. The market message is clear. Sustainability is essential now.

This guide will help you in the natural rubber yoga mat wholesale market. You’ll learn how to identify quality suppliers. You’ll evaluate products better. You’ll negotiate favorable terms. You’ll build partnerships that support long-term business growth. Based on my experience, these skills are essential for success.

Why I Recommend Natural Rubber Yoga Mats

Natural rubber yoga mats perform better than synthetic materials. I’ve seen how material choice impacts product quality, customer satisfaction, and brand reputation.

Material Composition and Safety Standards

Natural rubber comes from latex harvested from rubber trees (Hevea brasiliensis). This process creates a pure, chemical-free foundation. The material contains no PVC, phthalates, or synthetic polymers.

Non-Toxic Properties: Users practice breathing exercises on these mats. Natural rubber releases no harmful VOCs (volatile organic compounds). Synthetic alternatives often contain plasticizers and stabilizers. These chemicals can off-gas during use, especially in heated environments.

Allergen Considerations: Some practitioners have latex sensitivities. Quality suppliers now offer natural rubber mats processed to remove most allergenic proteins. I suggest you check certification and testing documentation from your wholesale partner.

Certification Standards: Look for suppliers providing OEKO-TEX, REACH, or similar certifications. These verify the absence of harmful substances throughout the manufacturing process.

Performance Characteristics vs Synthetic Materials

Real-world performance separates natural rubber from alternatives.

Grip and Traction:

– Natural Rubber: Provides superior grip that improves with light moisture. Downward dog positions stay stable even during intense flow sequences.

– PVC: Offers decent grip when new but degrades fast. Surface becomes slippery after 6-12 months of regular use.

– TPE: Lightweight but lacks grip in sweaty conditions. Practitioners often slip during hot yoga sessions.

Cushioning and Support:

– Natural Rubber: Dense cellular structure provides 4-6mm of effective cushioning. Supports joints without compromising stability.

– PVC: Compresses unevenly over time. Develops permanent indentations at high-pressure points (knees, hands).

– TPE: Too soft for balance poses. Lacks resilience for practitioners over 70kg.

Temperature Stability:

– Natural Rubber: Maintains properties in temperatures from 15°C to 40°C. Ideal for hot yoga studios.

– PVC: Becomes sticky above 30°C. Releases unpleasant odors in heated rooms.

– TPE: Softens too much in heat. Hardens in cold environments and becomes uncomfortable.

Durability and Long-Term Value

I recommend analyzing the investment. Natural rubber proves cost-effective.

Lifespan Comparison:

– Natural rubber mats: 5-8 years with regular use (4-5 sessions per week)

– PVC mats: 1-2 years before significant degradation

– TPE mats: 2-3 years with careful maintenance

Wear Patterns: Natural rubber shows minimal surface wear. The grip improves during the first 6 months as the surface breaks in. PVC flakes and peels. TPE develops smooth patches where grip disappears.

Cost Per Year Analysis:

– Natural rubber wholesale: $25-45 per mat ÷ 6 years = $4.17-7.50 per year

– PVC wholesale: $8-15 per mat ÷ 1.5 years = $5.33-10 per year

– TPE wholesale: $12-22 per mat ÷ 2.5 years = $4.80-8.80 per year

The higher upfront investment in natural rubber delivers better long-term value. Your customers replace mats less often. This reduces waste and builds brand loyalty.

Texture and User Experience

Practitioners notice immediate differences in feel and comfort.

Surface Texture: Natural rubber has a textured, grippy surface. It feels substantial and grounding. TPE often feels plasticky. PVC can be too smooth when new.

Weight and Portability: Natural rubber mats weigh 2-3kg for standard 4-5mm thickness. This density signals quality to consumers. TPE mats are lighter (1-1.5kg) but feel insubstantial. I find that weight becomes a feature, not a drawback, for studio-based practitioners.

Odor Profile: Fresh natural rubber has an earthy, mild rubber smell. This fades within 1-2 weeks of airing. PVC mats often carry a chemical smell that persists for months. Quality matters – premium natural rubber suppliers use better processing that minimizes initial odor.

Moisture Management: Natural rubber absorbs minimal moisture but provides grip when damp. This makes it ideal for vigorous practices. PVC becomes too slippery when wet. TPE falls between these extremes but performs inconsistent results.

Market Positioning and Customer Preferences

Consumer research shows clear preferences emerging.

Studios report that 70-80% of regular practitioners now request eco-friendly mat options. Natural rubber dominates this category. Retailers selling both natural rubber and synthetic options see rubber mats outsell PVC by 3:1 margins despite 40-60% higher price points.

Premium positioning works. Customers understand they’re paying for quality, safety, and sustainability. They’re willing to invest more upfront for products aligned with yoga’s values.

What to Look for in a Custom Yoga Mat Supplier

Choosing the right yoga mat wholesale supplier affects your product quality and business success. I’ve worked with dozens of manufacturers. The gap between suppliers is huge. Some give great value. Others cause expensive problems.

Manufacturing Capabilities and Production Capacity

Production capacity affects your ability to grow and meet market needs.

Minimum Order Quantities (MOQ): Good natural rubber mat suppliers need 100-500 units for first orders. This range lets small retailers test the market. Studios can build inventory. Some factories want 1,000+ unit minimums. I recommend avoiding these unless you have confirmed big demand.

Production Timeline: Standard lead times are 25-45 days for custom orders. This covers material sourcing, manufacturing, quality checks, and shipping prep. Rush production exists but costs 15-30% more. Plan your inventory at least 60 days ahead to skip premium fees.

Scaling Flexibility: Your supplier should handle volume growth without problems. A manufacturer handling 500-unit orders should manage 2,000-unit orders without quality drops. Ask about their production capacity per month. Good suppliers produce 10,000-50,000 mats each month across all clients.

Sample Production: Before big orders, ask for samples with your exact specs. Good suppliers give 2-3 sample mats for $50-150 with shipping. This saves you from expensive mistakes on bulk orders.

Eco-Certifications and Compliance Standards

Certifications prove supplier claims about green practices and safety.

Essential Certifications:

– OEKO-TEX Standard 100: Shows no harmful substances. This tests for 100+ chemicals including heavy metals, formaldehyde, and pesticides.

– REACH Compliance: European rules limiting dangerous chemicals. Critical if you sell in EU markets or want to show premium standards.

– SGS Testing: Independent check of product safety and quality claims.

– FSC Certification: For suppliers using green-managed rubber plantations.

Social Responsibility: BSCI or SA8000 certifications show fair labor practices. These matter for brand image. Aware consumers check your supply chain ethics.

Documentation Access: Quality suppliers share certification papers without hesitation. They renew certifications before they expire. Watch out for suppliers who delay or give expired certificates.

Custom Branding and Design Capabilities

Custom design turns plain products into branded assets that build customer loyalty.

Logo Application Methods:

– Silk Screen Printing: Most common method. Works well for simple logos with 1-3 colors. Good value for orders over 200 units. Pricing runs $0.50-1.50 per mat based on logo detail.

– Embossing: Makes raised logo marks. Premium look and feel. Lasts longer than printing. Costs $1-2 per mat. Needs custom molds ($70-200 one-time fee).

– Debossing: Sunken logo marks. Same benefits as embossing. Same pricing setup.

– Digital Printing: Allows full-color complex designs. Best for orders under 500 units. Costs $2-4 per mat. No mold fees.

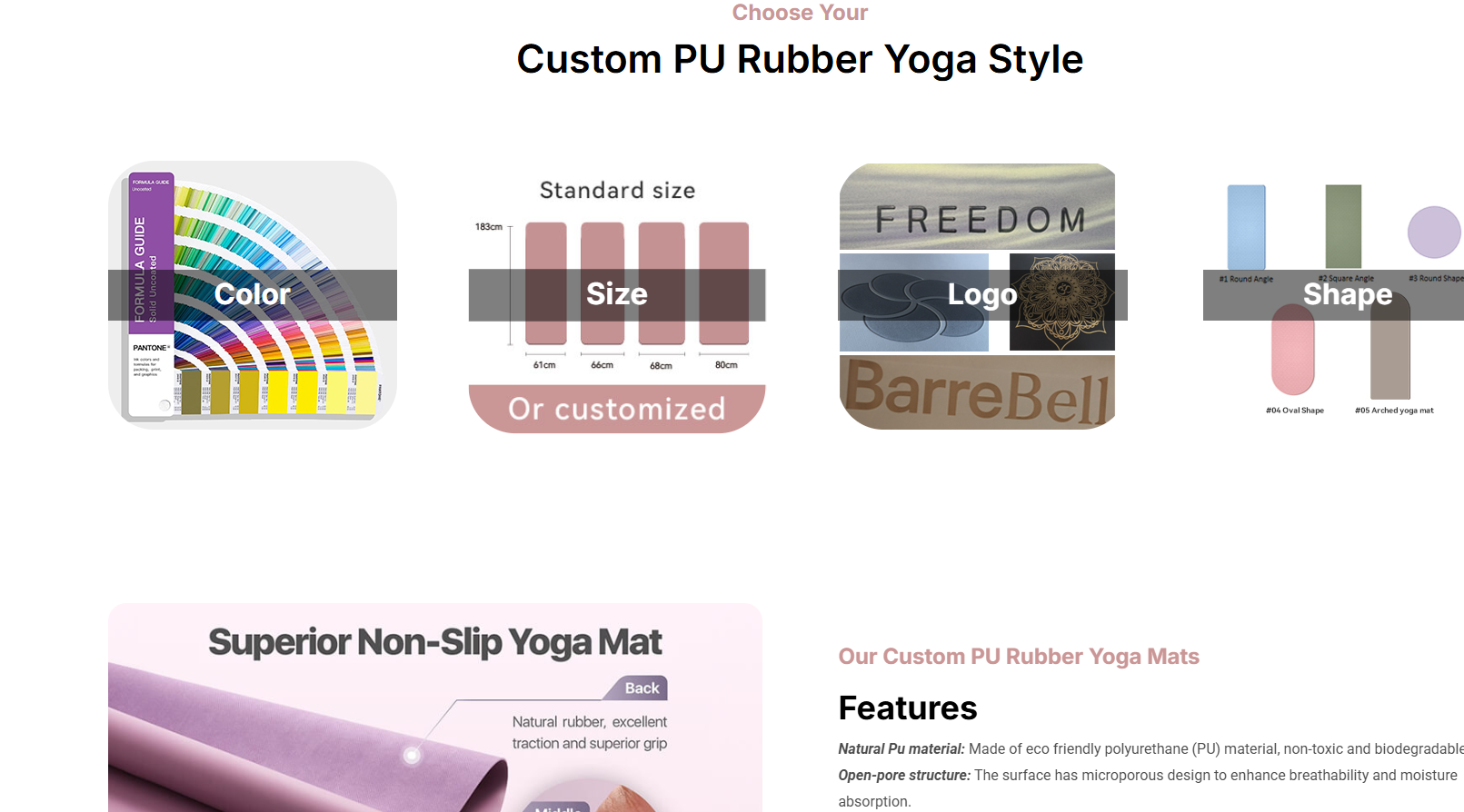

Color Customization: Natural rubber takes custom color mixes. Suppliers offer 20-50 standard colors at no extra cost. Custom color matching needs minimum orders of 300-500 units. Pantone matching services cost an extra $200-500 for formula work.

Size Variations: Standard yoga mat size is 183cm x 61cm. Suppliers should offer custom sizes for different markets. Extra-long mats (185-200cm) fit taller people. Wide mats (66-68cm) work for plus-size yogis. Custom sizing usually adds $2-5 per mat.

Texture Patterns: Surface texture affects grip and looks. Options include smooth, pebbled, geometric patterns, or custom designs. Pattern customization needs mold creation ($300-800) but makes your product stand out.

Production Standards and Quality Control

Good quality control stops bad products from reaching customers.

Inspection Protocols: Ask about quality checks throughout production:

– Raw material testing when received

– Checks during manufacturing

– Final product inspection before packing

– Random sampling from finished stock

Defect Rates: Industry-standard acceptable defect rates are 2-3% for natural rubber mats. Quality suppliers keep rates below 1%. Ask for data on their recent defect rates for similar orders.

Quality Issues to Monitor:

– Uneven thickness (should vary less than 0.2mm across mat surface)

– Air bubbles or voids in material

– Wrong printing or logo placement

– Color differences between mats in same batch

– Edge finishing quality and straightness

Third-Party Inspection Services: For large orders, consider hiring outside inspection companies. SGS, Bureau Veritas, or Intertek do pre-shipment checks for $200-400. This protects against getting bad products.

Communication and Customer Service

Quick communication stops mix-ups and fixes issues fast.

Language Capabilities: Your main contact should speak your language well. Mix-ups about specs cause expensive errors. Test communication during first questions. Unclear or slow replies mean future problems.

Technical Knowledge: Sales reps should know product specs well. They should answer questions about material traits, customization limits, and production methods. Shallow knowledge suggests limited factory access or experience.

Response Times: Quality suppliers reply to questions within 24 hours on business days. Delays past 48 hours show weak customer service setup.

Problem Resolution: Talk about how they handle quality issues or shipping problems before ordering. Clear rules for replacing bad products, shipping damage claims, and dispute solving protect your money.

Logistics and Shipping Capabilities

Good logistics make sure products arrive on time and in sellable shape.

Shipping Methods: Suppliers should offer several options:

– Sea Freight: Most affordable for orders over 200 units. Transit times 25-45 days based on location. Cost example: 500 mats from China to US West Coast runs $800-1,200.

– Air Freight: Faster (5-10 days) but expensive. Good for rush orders or high-value small amounts. Same 500-mat shipment costs $3,500-5,000.

– Express Courier: DHL, FedEx, UPS for samples or urgent small orders. Expensive per unit but fast (3-7 days).

Freight Terms:

– FOB (Free on Board): You arrange and pay for shipping from the departure port. Gives you shipping control but needs logistics know-how.

– CIF (Cost, Insurance, Freight): Supplier arranges shipping to your port. Simpler but may cost more.

– DDP (Delivered Duty Paid): Supplier handles everything including customs clearance and delivery. Easiest option. Usually costs 15-25% more than FOB.

Packaging for Transit: Mats should be well protected during international shipping. Quality suppliers use:

– Individual bags for each mat

– Carton boxes with good cushioning

– Pallets for container shipments

– Waterproof wrapping for sea freight

Tracking and Documentation: Suppliers should give complete shipping papers including commercial invoices, packing lists, bills of lading, and tracking numbers. These papers help with customs clearance and delivery.

Supplier Reputation and Track Record

Past performance predicts future reliability.

Years in Business: Proven suppliers (5+ years) show stability. They’ve handled market changes and solved production problems. New makers may offer lower prices but carry higher risk.

Client Portfolio: Ask for references from current customers in similar business spots. Studio owners should talk to other studio clients. Retailers should connect with retail buyers. Ask references about quality steadiness, communication, and problem solving.

Factory Verification: For big partnerships, check the supplier runs actual manufacturing facilities. Factory addresses should match business records. Video calls touring facilities prove they’re real. Trade shows give chances to meet suppliers face-to-face.

Online Presence: Professional websites, active social media, and good reviews show proven operations. Check sites like Alibaba, Global Sources, or Google Business for ratings and feedback. Watch out for suppliers with minimal online presence or many bad reviews.

Top Custom Natural Rubber Yoga Mat Supplier for Wholesale

I recommend finding reliable yoga mat suppliers who deliver consistent quality. This separates successful yoga businesses from struggling ones. I’ve researched the market and identified manufacturers who excel in natural rubber mat production.

FDM Yoga – Premium Eco-Friendly Manufacturing Leader

FDM Yoga stands out as a top-tier manufacturer in the natural rubber yoga mat industry. Their reputation comes from years of delivering quality products to demanding markets.

Core Strengths:

– Custom Print Capabilities: They offer all major logo application methods. Silk screen printing starts at $0.60 per mat for simple designs. Embossing services run $1.20-1.80 per mat. One-time mold fees cost $70-200. Digital printing handles complex full-color designs at $2.50-3.50 per mat.

– Bulk Pricing Structure: Their volume discounts make scaling affordable. Orders of 200-499 units get 3% off base pricing. Orders of 500-999 units receive 6% discounts. Orders over 1,000 units earn 8-12% price reductions.

Production Capacity: FDM Yoga makes 25,000-35,000 mats each month across all product lines. This volume ensures they handle growth without quality drops. New clients start with 100-unit minimums. I find this works well for testing markets.

Client Base: Studios from North America, Europe, and Australia make up 60% of their business. Retail brands account for 30%. The remaining 10% serves yoga teacher training programs and wellness centers. This diversity shows they understand different market needs.

Quality Testing: Every production batch undergoes density testing (maintaining 1.15-1.25 g/cm³). They verify tensile strength (minimum 16 MPa). They check elongation (450-550%). Third-party SGS testing happens four times per year. Clients receive reports.

Lead Times: Standard production runs 30-35 days from deposit to shipping readiness. Rush production (20-25 days) adds 20% to base pricing. Sample production takes 7-10 days. Costs range from $80-120 including express shipping.

Certifications Portfolio:

– REACH compliance documentation

– SGS testing reports (updated four times per year)

– BSCI social compliance audit (Grade B rating)

Communication: English-speaking account managers respond within 12-18 hours on business days. Technical questions get forwarded to production engineers. They provide detailed answers within 24 hours.

Conclusion

After years in this industry, I’ve learned that success comes down to one thing: choosing partners who share your commitment to quality and sustainability. The right natural rubber yoga mat supplier doesn’t just fill orders—they help you build a brand your customers trust and recommend. Start with small test orders, verify everything I’ve outlined here, and don’t let price alone drive your decisions. Your reputation depends on the mats your customers roll out every single day, and that’s worth getting right from the start.