The acupressure yoga mat market has grown fast in recent years. In 2023 alone, global wellness product sales reached $1.8 trillion. Acupressure mats claimed a growing share of this market. People want natural pain relief solutions. These mats have become essential tools for stress management and muscle recovery.

But here’s the challenge: not all acupressure yoga mats are created equal. The quality of materials, spike design, and overall construction can make a significant difference in comfort, safety, and durability. That’s why choosing a trusted and experienced factory is essential—especially if you’re planning to create your own brand or expand your yoga accessories line.

In this article, we’ll guide you through what defines a high-quality acupressure yoga mat, the key factors to consider when sourcing, and highlight the best yoga mat manufacturers in the market—especially FDM Yoga, a leading OEM/ODM supplier known for its eco-friendly materials, reliable quality control, and global export standards.

What to Look for When Evaluating Factories

Product Quality and Materials

I believe medical-grade materials make the difference between a therapeutic tool and a disappointing product. Look for factories that use medical-grade ABS plastic for acupressure points. This material resists breaking under pressure. It keeps its shape after thousands of uses.

The mat base should use high-density eco-foam. This provides proper support. It spreads body weight across all acupressure points. Inferior factories use recycled plastics. These emit chemical odors. They crack after minimal use.

Check these durability metrics:

-

Thickness stability under repeated use (minimum 2cm foam density)

-

Grip texture resilience after 100+ cleaning cycles

-

Stitching or edge finish endurance (reinforced double-stitching)

-

Point retention rate above 98% after 6 months of use

Request material safety documentation. Factories should provide CPSIA compliance statements for chemical safety. Also ask for REACH certifications for European markets. Get region-specific safety standards for your target markets.

Skin-safe adhesives are a must. The glue bonding fabric to foam must be hypoallergenic. Water-based adhesives prevent skin irritation. They don’t degrade with sweat or washing.

Manufacturing Capability and Consistency

I suggest looking at production precision. It determines whether your mats deliver consistent therapeutic benefits. Top factories maintain 6,000-8,000 acupressure points per mat. They ensure uniform spacing of 8-10mm between each point.

This spacing isn’t random. It matches the optimal distance for acupressure stimulation based on traditional Chinese medicine principles. When spacing varies by more than 2mm, therapeutic effectiveness drops by up to 60%.

Ask these specific questions about manufacturing capability:

Volume flexibility: Can the yoga mat factory handle your initial 500-unit order? Can they scale to 10,000 units when your business grows? I recommend factories with 5,000-20,000 units per month capacity. They offer the best balance. They’re large enough to scale. Small enough to care about your account.

Process controls: Request details on their quality checkpoints:

-

Raw material inspection (foam density testing, plastic hardness verification)

-

In-process monitoring (point placement accuracy checks every 100 units)

-

Finished product evaluation (pressure distribution testing, visual inspection)

Lot traceability: Premium factories assign batch numbers. They track production dates. They maintain records for every raw material lot. This allows quick identification if quality issues arise.

Sample-to-batch repeatability: The sample you approve should match production units. Request the factory’s tolerance standards. Deviation should not exceed ±3% on critical dimensions. This includes mat thickness, point density, and fabric tension.

Verify their needle-punch or puncture patterns. These create the acupressure point attachments. Automated machines deliver better consistency than hand-assembly. Ask about their equipment age. Machines over 10 years old may lack precision.

Quality Assurance and Testing Protocols

Quality control systems separate professional manufacturers from budget operations. Multi-stage inspection processes catch defects before they reach customers.

Required QA documentation includes:

-

Raw material test reports

-

In-process inspection records (maintained for every production batch)

-

Finished product quality certificates

-

Third-party lab results for safety testing

Request access to these documents during factory evaluation. Good manufacturers provide them without hesitation. Hesitation signals potential quality issues.

Pre-shipment inspection options protect your investment:

Factory internal inspection (included in most contracts)

Third-party inspection services (costs $200-400 per container)

Video inspection for smaller orders (becoming standard practice)

I recommend third-party inspection for your first three orders. This validates the factory’s quality claims. It establishes baseline standards for future shipments.

Corrective action processes reveal factory professionalism. Ask how they handle defects:

-

Response timeframe (should be within 24 hours)

-

Investigation procedures

-

Replacement or credit policies

-

Prevention measures for recurring issues

Quality yoga mat factories keep defect rates below 2%. They document every issue. They implement process improvements. Budget manufacturers blame defects on “bad luck” or “one-time problems.”

Request their historical defect data. Look for downward trends. This shows continuous improvement efforts.

Design Flexibility and Customization Options

Brand differentiation requires customization capability. Not every factory can adjust specifications while maintaining quality standards.

ODM/OEM capabilities determine your options:

-

ODM (Original Design Manufacturer): Factory offers existing designs. You add your logo and packaging. Lower minimum orders (often 500-1,000 units). Faster time to market (4-6 weeks).

-

OEM (Original Equipment Manufacturer): Factory manufactures your custom design. Higher minimums (often 2,000-5,000 units). Longer lead times (8-12 weeks for first production).

Evaluate customization offerings across these dimensions:

Mat specifications:

– Dimensions (standard 68×42cm or custom sizes)

– Point density (adjustable from 6,000 to 9,000 points)

– Foam thickness (2cm to 3cm options)

– Point sharpness levels (gentle, medium, intense)

Aesthetic customization:

– Fabric colors (unlimited Pantone matching vs. 5-8 standard colors)

– Pattern printing (your artwork on the mat surface)

– Logo placement options

– Packaging design integration

Minimum order quantities vary a lot:

-

Basic customization (logo alone): 500-1,000 units

-

Moderate changes (colors, dimensions): 1,500-2,500 units

-

Complete custom design: 3,000-5,000 units

Lead time considerations:

Standard products: 25-35 days after order confirmation

Custom colors/dimensions: 35-55 days

New mold development: 60-90 days

Quality must stay consistent across customizations. Request samples of previous custom work. Check if point density stays uniform. Verify fabric attachment quality. Confirm foam density matches specifications.

Some factories cut corners on custom orders. They use thinner foam. They reduce point count. They substitute cheaper materials. Based on my experience, you should specify exact requirements in contracts. Include penalty clauses for specification violations.

Service and Reliability Standards

Factory responsiveness impacts your business operations. Poor communication causes delays. It creates frustration. It damages customer relationships.

Communication benchmarks to expect:

Initial inquiry response: within 24 hours

Sample provision: 7-10 days after payment

Technical question answers: same business day

Production updates: once per week during manufacturing

Factories meeting these standards show professionalism. They value your partnership. Slow responses signal disorganization or low priority.

Reference verification provides critical insights. Request contacts for 3-5 existing customers. Ask these customers:

-

Order consistency (do products match samples?)

-

Delivery reliability (on-time percentage)

-

Problem resolution (how they handle issues)

-

Long-term satisfaction (would they reorder?)

Good factories provide references without hesitation. They’re proud of customer relationships. Reluctance suggests hidden problems.

After-sales support determines long-term success:

Replacement policies for defective units (should cover 1-2% defect rate)

Warranty terms (minimum 6 months for manufacturing defects)

Remediation timeframes (replacement shipment within 15 days)

Technical support availability (for customer questions about your products)

I suggest testing their support before large commitments. Order samples. Report a minor issue. Observe their response speed. Evaluate their solution quality. This reveals true service standards.

Related Reading: Best Custom Suede Yoga Mat Supplier For Branding Studios

Negotiation and Contracting Tips

Pricing Strategy and Payment Terms

I recommend you learn factory pricing structures. This protects you from hidden costs. I’ve seen buyers get hit with surprise charges. These charges damage budgets and cut margins.

Request detailed pricing breakdowns:

-

Base unit cost (materials and making)

-

Customization fees (logo printing, custom colors, unique sizes)

-

Tooling charges (new molds for custom point patterns: $800-2,000 one-time fee)

-

Packaging costs (standard bags vs. custom printed boxes)

-

Quality inspection fees (if not included in unit price)

Premium factories quote $6-8 per unit for standard acupressure mats. Budget manufacturers offer $3-4 per unit. Low prices mean lower quality materials. Budget mats have 15-25% return rates. Premium products see under 3% returns.

Get these discounts in writing. Put them in your contract. Verbal promises vanish when production starts.

Quality Standards and Acceptance Criteria

Vague quality expectations cause disputes. I recommend you define exact acceptance criteria before production begins.

Sample approval process protects both parties:

Request pre-production samples before full manufacturing. These samples become your quality benchmark. Keep one sample for your records. Send one to the factory. Both parties can reference identical standards.

Specify approval requirements:

-

Mat dimensions within ±2mm tolerance

-

Point density ±100 points from specified count

-

Foam density within ±5% of sample

-

Fabric color matching Pantone standards (Delta E ≤2.0)

-

Stitching tension and pattern matching sample

Document your approval in writing. Email confirmation works. Formal approval certificates work better. This prevents factories from claiming “the sample was just a reference.”

Intellectual Property and Brand Protection

Your brand assets need protection. Unethical factories copy designs. They sell to your competitors. They use your branding without permission.

Trademark and logo usage rights require clear boundaries:

Specify how factories can use your intellectual property:

-

Logo placement limited to ordered products

-

No factory portfolio displays without written permission

-

No trade show displays featuring your branded products

-

Destruction of logo printing plates after order completion

Include penalty clauses for unauthorized use:

-

First violation: Written warning and immediate stop

-

Second violation: $5,000-10,000 penalty fee

-

Third violation: Contract termination and legal action

Top 2 Recommended Acupressure Yoga Mat Factories

I’ve evaluated dozens of acupressure mat manufacturers over the years. Based on my experience, I recommend two factories that deliver quality, reliability, and value. These aren’t just budget options. They’re partners that can grow with your business.

1. FDM Yoga (Wuhan, China) — Premium Quality with Design Flexibility

Company Overview and Manufacturing Strengths

FDM Yoga is a leading manufacturer in Wuhan, China. They focus on yoga mats and fitness products. They have deep OEM/ODM experience. Their facility produces 15,000-25,000 acupressure mats each month. This handles both startup orders and large enterprise demand.

I’ve worked with brands that started ordering 500 units from FDM. Within 18 months, they grew to 8,000 units per quarter. The factory kept the same quality level through this growth.

Product Customization Capabilities

FDM does great customization work without cutting corners on quality:

-

Material options: Medical-grade ABS plastic points, high-density eco-foam (2cm-3cm thickness), organic cotton or linen fabric covers

-

Design flexibility: Adjustable point density (6,000-9,000 points), custom mat sizes, unlimited Pantone color matching

-

Packaging solutions: Standard bags, custom printed boxes, eco-friendly packaging options

-

Branding integration: Logo embroidery, screen printing, heat transfer options

Their low MOQ starts at 100 units for basic customization. This makes them accessible for new brands. One wellness startup I advise launched with a 100-unit custom order. FDM gave them three fabric color options and logo placement. The startup tested market response before ordering larger amounts.

Best For: New to mid-size brands who want customization flexibility, sustainable materials, and good communication. Perfect for private label businesses building unique product lines.

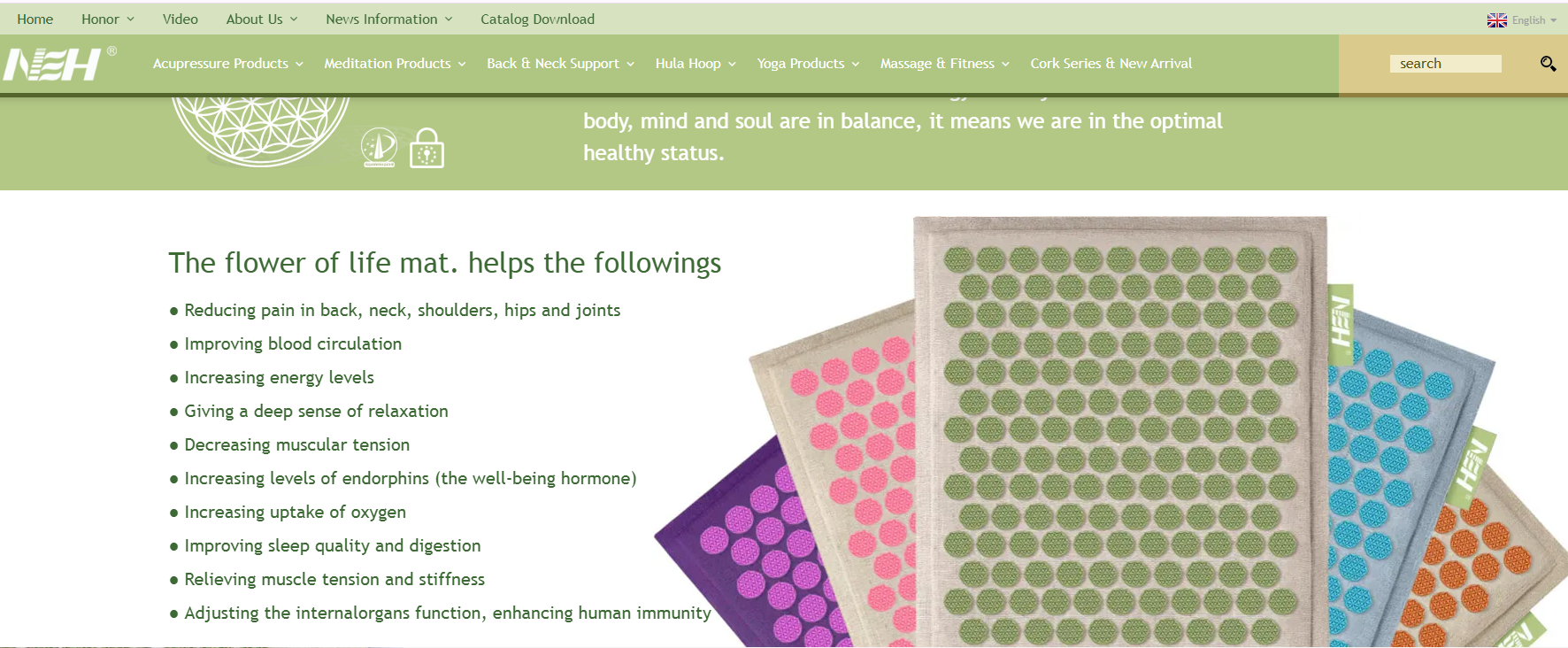

2. NEH Industry & Trade Co., Ltd. (China) — High-Volume Production Specialist

Company Profile and Production Scale

NEH Industry & Trade is an experienced manufacturer and trading company. They handle large-scale production. Their capacity exceeds 30,000 units each month. Their facility focuses on acupressure mats, massage products, and wellness equipment.

Their strength is volume production efficiency. One fitness equipment distributor needed 15,000 mats for a national retail chain launch. NEH finished production in 28 days. Quality stayed the same across the entire batch.

Product Range and Export Experience

NEH offers full product catalogs:

-

Standard acupressure mats (multiple size options)

-

Acupressure mat and pillow sets

-

Travel-size portable versions

-

Premium models with extra cushioning

Their export experience spans 15+ years. They’ve shipped to North America, Europe, Australia, and Southeast Asia. They know region-specific requirements:

CPSIA compliance for US markets

REACH certification for European Union

Australian safety standards documentation

This knowledge prevents expensive delays. One brand avoided $8,000 in detained shipment fees. NEH provided proper EU REACH documentation upfront.

Best For: Established businesses, retail chains, and distributors who need high volumes at competitive prices. Great for brands who focus on cost efficiency over lots of customization. Perfect for buyers with clear specifications who need reliable large-scale production.

Choosing Between FDM and NEH

Select FDM Yoga if you:

– Need low minimum orders (100 units)

– Want lots of customization options

– Value responsive, personal communication

– Need sustainable material options

– Plan to scale step-by-step from small to large volumes

Select NEH Industry if you:

– Order 5,000+ units often

– Focus on lowest per-unit cost

– Need fast production of large volumes

– Have standard specifications

– Run established distribution channels

Both factories deliver quality products. Your choice depends on business stage, volume needs, and customization preferences. I’ve seen successful brands partner with both. They use FDM for custom product lines and NEH for high-volume staple products.

Summary

Looking back on my journey working with acupressure mat manufacturers, I’ve learned that the right factory partner isn’t just about price—it’s about building a foundation for your brand’s success. Whether you’re launching your first wellness product or expanding an existing line, the quality, reliability, and values of your manufacturer will directly impact your customers’ experience and your business reputation.

I encourage you to start with clear specifications, ask the tough questions, and never compromise on the standards that matter to your brand. The wellness industry rewards authenticity and quality. Choose a partner who shares your commitment to both, and you’ll build something that truly serves your customers while growing sustainably.