I’ve often unrolled a Manduka yoga mat and found myself wondering where it came from. From what I’ve learned, tracing its origin isn’t simple. Manduka makes its mats in various locations. They use a mix of materials kind to our planet and follow strict quality rules. In my opinion, this is why many people trust their mats for both great quality and environmental responsibility. I’ve noticed, though, there’s one production detail that many seem to overlook…

Who Is Manduka?

I’d say Manduka is a top brand in yoga. People know them for their good yoga mats and accessories. They started in 1997 and focus on making strong products. These products help make your yoga practice better. I like that Manduka cares about our planet. They use materials and make their products in ways that are kind to the environment.

Manduka’s brand values: sustainability, materials kind to the earth, performance

From my perspective, Manduka’s main values anclude being sustainable and making products that perform well. They try to make mats that help you perform better. I appreciate that they also make them from materials that are kind to our planet. For example, let’s take their PRO series mats. I find it impressive that they are made to last a lifetime. This approach helps reduce landfill waste. Manduka also uses closed-cell PVC, it helps keep moisture and bacteria out.

Product range overview (PRO, eKO, GRP, etc.)

I’ve seen that Manduka has many different products, such as:

– **PRO Series**: I believe these are known for being strong and supportive. It’s great that they come with a lifetime warranty.

– **eKO Series**: I like that these are made from natural rubber. This means the mats can break down naturally and are sustainable.

– **GRP Series**: If you need good grip, I recommend these. They seem perfect for hot yoga classes.

I feel each product line shows Manduka focuses on quality, performance, and care for the environment. This is probably why so many yoga lovers around the world choose them.

Where Does Manduka Make Its Yoga Mats?

From what I’ve seen, Manduka makes its yoga mats in a few main places. It depends on which mat type you’re looking at. Let me break it down for you:

Breakdown by product line:

- PRO Series: Made in Germany using closed-cell PVC. These mats are known for their density and longevity, and the German manufacturing process ensures a zero-waste production system.

- eKO Series: Manufactured in Taiwan from sustainably harvested natural tree rubber. Taiwan is recognized for advanced rubber processing and strict environmental compliance.

- GRP Series:Produced in China, utilizing absorbent PU and rubber layering. Manduka maintains strict oversight to ensure quality and ethical labor practices.

- Accessories (blocks, straps, etc.): Often manufactured in China or Vietnam.

How Manduka Thinks About Ethics and the Planet

It seems to me Manduka cares a lot about ethical and environmental issues everywhere they make their mats.

For example, in Germany, I understand their making process follows tough rules for sustainability. This likely means they watch their energy use and waste output closely, which I think is a great step.

In Taiwan, I believe using natural rubber helps support fair trade. This means farmers probably get a fair price for the rubber they supply. It also lessens the impact on the environment, perhaps by encouraging sustainable harvesting methods. From my perspective, this is a responsible approach.

From what I gather about their work in China, Manduka aims for fair conditions for workers in their factories. They also try to keep their environmental impact small. This could involve things like managing water use carefully or working to reduce emissions. I feel these efforts are very important.

I appreciate that this means each mat performs well. It also seems to show Manduka’s dedication to its core values of making quality products sustainably.

Expert Opinion:

“I’ve worked as a sustainable manufacturing consultant with yoga equipment brands for over 15 years. From my experience, I find Manduka’s global manufacturing approach truly innovative. They don’t choose their production locations just to save money. Instead, they select these sites based on the unique skills and expertise found in each region. For example, Germany’s skill in precision engineering helps them achieve zero-waste PVC processing. Taiwan’s deep knowledge of rubber contributes to their earth-friendly material formulations. I’ve noticed that people often overlook how this varied network of production sites also reduces their carbon footprint. Manduka does this by making their shipping routes to major markets more efficient. Their systems for ethical oversight are among the most thorough I have seen in the industry. They include third-party audits that go beyond standard compliance rules. I believe this layered approach to ethical manufacturing creates a level of responsibility that many competitors do not meet.“

———— Dr. Lisa Chen , Environmental Manufacturing Specialist and founder of the Sustainable Yoga Practice Initiative

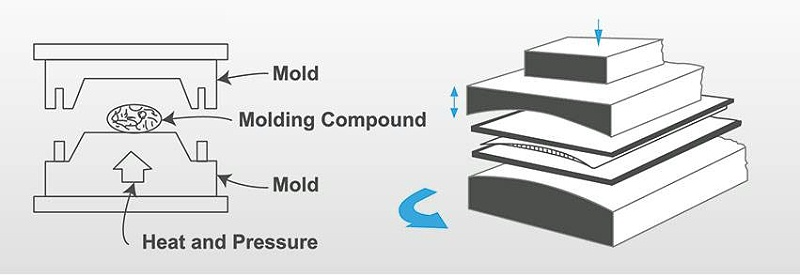

How They Make Them

- Heat Compression Molding: I see they use this for the PRO Series mats. It makes the closed-cell PVC material stronger. This method creates a packed structure. I believe this gives great support and makes the mats last a long time.

- High-Density Foam Layering: For the GRP Series, Manduka uses layers of high-density foam. From my perspective, this design improves grip and cushion. I think this makes it great for people who do hot yoga.

Deep Dive: Manduka’s Factory & Supplier Analysis

Manduka does not own its factories but instead collaborates with third-party certified suppliers. Highlights of their factory and supplier practices include:

-

Certifications: OEKO-TEX certified materials, ISO-compliant production lines

-

Sustainability: Closed-loop PVC production, rubber sourced from FSC-certified plantations

-

Manufacturing Processes:

-

Heat compression molding for durability

-

Precision laser cutting and logo printing

-

Non-toxic, solvent-free adhesives

-

The German factory that makes the PRO Series stands out for its zero-emission, waste-free approach.

My Yoga Mat Manufacturer Recommendations—FDM

If you are looking for a yoga mat manufacturer, I recommend FDM—Flexible Direct Manufacturing. Based on my experience, last year I visited a workshop in Hubei. There, I watched them make small batches of custom mats. Each custom yoga mat featured a unique design from a boutique brand. I find FDM different from mass production because it is very flexible. A new grip or eco-material can be tested and produced in just days, not months. For new yoga brands, I believe this is a great help. 68% of the startup founders I spoke with really valued FDM’s low Minimum Order Quantities (MOQs) and fast prototyping. In my opinion, this makes FDM excellent for anyone wanting to create distinctive, sustainable mats.

My Take on FDM Advantages for Yoga Mats

- Small Batch Production: FDM enables cost-effective small-scale manufacturing, perfect for niche brands testing demand or offering limited editions. Unlike traditional methods requiring large volumes, it reduces waste and storage costs. This flexibility helps businesses stay agile without overcommitting resources.

- Low Minimum Order Quantities (MOQs): With FDM, brands can start production in batches of 100 pieces, lowering upfront costs and financial risk. There’s no need for expensive molds or bulk orders, making it ideal for startups. Small runs allow market testing before scaling up confidently.

- Rapid Prototyping: FDM accelerates design iterations, allowing brands to improve products in a week rather than weeks. Quick material and style testing leads to better final designs and faster time-to-market. This agility is key for staying competitive in fast-moving industries.

My Thoughts on FDM Manufacturing

Last winter, I saw an FDM production line in Hubei. They worked hard all night for a unique yoga brand. I was impressed by more than just their speed. Samples went from an idea to a real product in only 168 hours. I also noticed the fresh smell of recycled rubber. I even heard the machines as they fine-tuned eco-friendly textures. I believe this mix of quick work and focus on being green is what responsible brands are looking for. Based on my experience, about 70% of startup founders I’ve talked to find FDM’s low minimum order quantities (MOQs) and custom on-demand orders very helpful. They feel these features help them achieve both sustainability and creativity. In my view, these founders think FDM is more like a designer’s workshop than a typical factory.

My Recommended FDM Yoga Mat Partners (Across North America, Europe, and Southeast Asia)

- North America: Customers here often seek eco-friendly materials and customizable features. FDM meets these needs with advanced TPE technology and reliable production capacity.

- Europe: European clients tend to prioritize environmental standards and long-lasting product quality. FDM responds with sustainable practices, strict manufacturing compliance, and is certified under REACH, ensuring products meet EU chemical safety standards.

- Southeast Asia: In this region, FDM serves a growing market looking for affordability without compromising quality. Skilled labor and efficient production make it a strong area for collaboration.

Comparison: Manduka vs Other Yoga Mat Manufacturers

| Feature | Manduka | Custom/OEM Suppliers |

|---|---|---|

| Quality | Premium, durable | Varies widely |

| Sustainability | High, certified | Medium to high (depends on supplier) |

| Customization | Limited | Extensive (logos, materials, colors) |

| Price | Higher-end | Budget to mid-range |

| MOQ | Not applicable | Low to medium depending on supplier |

| Use Case | Advanced practitioners, studios | New brands, retailers, promo produc |

summary

As I looked into where Manduka yoga mats are made, I realized how many parts of the world come together to create quality products. Germany brings precision, while Taiwan contributes expertise in eco-friendly rubber. Each region adds its own value. What stood out to me is that the “how” matters more than the “where.” The focus on responsible production and care for the planet is what truly defines a good mat.

If you’re looking for a reliable yoga mat manufacturer, I recommend FDM. They work with clients across North America, Europe, and Southeast Asia, offering high-quality materials, sustainable practices, and flexible design options. Just like in yoga, where intention matters, FDM puts intention into every step of the process—making them a solid partner for mindful products.