Sourcing yoga mats in bulk can feel confusing, right? There are so many ways to buy—some seem quick, others claim to be cheap, but figuring out what actually saves you money isn’t easy. If you’re looking for the best value, cutting out the middleman might be the game changer you need. But there’s one crucial thing that many buyers still overlook…

Understanding the Yoga Mat Wholesale Landscape

In my experience, the yoga mat wholesale market has several ways to buy. Each way has its good and bad points. I believe it’s very important for you, as a buyer, to know these options. This will help you get the best prices and good quality.

Common Purchasing Channels

In my experience, wholesale buyers mainly choose from four paths:

| Channel | Typical Mark-up | Pros | Cons |

|---|---|---|---|

| Domestic distributor | 25–60 % | Local inventory, quick turnaround | Highest per-unit cost |

| Trading company | 15–40 % | Handles export paperwork, English support | Extra margin layer |

| Online wholesale platforms | 10–35 % | Wide vendor pool, easy price compare | Quality variance, service fees |

| Factory direct (OEM/ODM) | 0–10 % | Lowest base cost, customization | Requires due diligence, larger MOQs |

I find that many buyers see a big cost benefit when they buy straight from the yoga mat factory. You skip the middleman’s markup. I suggest this route because it can save you a lot of money. This is very true if you are placing big orders.

My Thoughts on Saving Money with Factory Direct

If you buy straight from the maker, I believe you get the lowest starting prices. I like this way because you can also ask for custom changes. For example, you can specify the mat’s thickness, the materials used, or add your own branding. But, I must point out, you should be aware of bigger minimum order quantities (MOQs). I also recommend you check carefully. Make sure the factory meets your quality and rule standards.

So, in my opinion, getting to know the wholesale scene is really important. It helps you make smart buying choices. These choices should fit your budget and what you expect in terms of quality for yoga mats.

What Is Factory Direct Supply?

With factory direct supply, you place your order straight with the maker. I think this is smart. It means no middlemen like agents, distributors, or brands that license products are adding extra costs. As a buyer, I find this approach can greatly reduce your expenses.

Benefits I See with Factory Direct Supply

- Save Money: When you cut out the middleman, you can get lower prices. Based on my experience, this is often just a 0–10% mark-up from the factory’s cost. I’ve seen this is very good for large orders.

- Make it Your Own: You can ask the factory to change product details. For example, I’ve found it useful when you want:

- Different mat thickness

- Specific materials

- Customized packaging

- Your own brand logo

I recommend exploring this, as it helps your product stand out.

What Buyers Should Consider

Yoga mat factory direct supply has great benefits. But, I suggest you also think about some possible challenges:

– Larger Orders Needed (MOQs): Factories often need you to buy in large amounts. From what I’ve observed, this is because they optimize production for big runs. This might not work for every buyer.

– Check Quality: I recommend you research the factory well. Make sure they will meet your quality expectations and any rules you must follow. For instance, I’d ask about their certifications or look for past client reviews if you can.

To sum up, I believe knowing about factory direct supply is a good way for you to get quality yoga mats at the best prices.

Five Reasons Factory Direct Is More Cost-Effective

I find that buying custom Yoga mats from the factory saves a lot of money. Let me share five clear reasons why this method helps wholesale buyers save more money.

Lower Per-Unit Cost

I believe buying from yoga mat manufacturers gives you the lowest starting prices. Factories often give ex-works (EXW) or FOB prices. These prices don’t have distributor mark-ups. In my experience, you can expect prices 20–40% cheaper than domestic resellers. This way usually means a mark-up of only 0–10% from the factory’s cost. Plus, I recommend negotiating volume breaks and annual call-off contracts. This way, you save even more money.

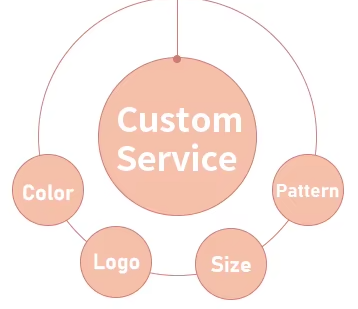

Customization Without the Premium

I’ve found that buying from the factory lets you customize your yoga mats without high costs. Do you need TPE instead of PVC? Maybe you want specific colors matched to Pantone standards. Or perhaps you’d like features such as edge stitching and laser-engraved logos. From my perspective, adding these custom features in-house is much cheaper. It costs less than aftermarket printing or re-branding.

Bulk-Order Economies of Scale

In my experience, factories give better prices for larger orders through tiered pricing. So, if you buy in bulk, the cost of production molds spreads over more yoga mats. This lowers your cost for each mat. I think this benefit is very helpful for larger retailers. It helps them improve their profits.

Streamlined Order Process

Dealing directly means a simpler process from factory to you. Fewer middlemen mean faster production. It also lowers the chances of delays or miscommunication. In my view, you can talk straight to engineers. This speeds up sample changes and quality checks. I suggest this approach to ensure your orders meet your needs without annoying setbacks.

Stronger Ties with Suppliers

I find that building a long-term bond with yoga mat factory partners offers more good things. For instance, you might get better payment terms or have your orders prioritized. You could even work together on new textures or eco-friendly materials. Resellers often can’t offer these perks. That’s why, in my opinion, partnering directly with factories greatly helps your business grow.

Potential Challenges (and How to Beat Them)

Buying directly from yoga mat factories offers big benefits. But, you might face some issues. Knowing these issues helps you choose wisely when buying yoga mats in bulk.

Common Challenges and Solutions

I’ve listed some common problems below. I’ve also included solutions that, in my experience, work well:

| Challenge | Solution |

|---|---|

| High minimum order quantity (MOQ) | Pool orders with partners, start with mixed SKUs, or negotiate trial MOQ. |

| Quality control | Request third-party inspections (Pre-Production, During Production, Pre-Shipment) and insist on material certificates (RoHS, REACH, BSCI). |

| International logistics | Compare freight forwarders, factor in duties, use palletized shipping to reduce damage. |

| Language & time-zone gaps | Work with bilingual sales reps, schedule standing video calls, agree on written spec sheets. |

Larger Order Requirements

Factories often ask for big orders. This can be a problem. You might not need to buy so much at once. This makes it tough. To handle this, I think teaming up with other businesses for orders is a good idea. You could also start by ordering a mix of different products (SKUs). Another way is to talk to the factory about a smaller trial order (MOQ).

Ensuring Quality Control

Making sure products meet your quality standards can be tricky. I believe you must research the factory well. You also need to set up tough quality checks. I recommend hiring independent inspectors. They should check items before production, during production, and before shipping. This gives me peace of mind. Also, it’s very important to ask for papers like RoHS, REACH, or BSCI. These show the materials are safe and meet standards. From my experience, this protects your business.

Handling International Logistics

Shipping items from other countries can make buying things more complex. You should compare different shipping companies. This helps you find the best one for your needs. Remember to include costs like import duties and taxes in your budget. I suggest using palletized shipping. This method helps reduce damage to your yoga mats while they are being moved. I’ve found this to be very effective.

Dealing with Communication Barriers

Different languages and time zones can make talking to factories hard. I find it helpful to work with sales staff who speak both your language and the factory’s language. This makes conversations easier. Setting up regular video calls is a good way to keep communication clear. I try to do this weekly if possible. Finally, make sure you both agree on written product details (spec sheets). This prevents mistakes and ensures you both understand the requirements. This has saved me a lot of trouble.

How to Find a Reliable Yoga Mat Manufacturer

Finding a reliable yoga mat manufacturer is crucial for ensuring quality and cost-effectiveness in your wholesale purchasing. Here are key strategies to help you identify trustworthy suppliers.

Research on B2B Platforms

Start by exploring B2B platforms like Alibaba, Global Sources, or Made-in-China. Filter for verified factories with good ratings, several years in business, and ISO-certified facilities. This helps ensure that you are dealing with reputable manufacturers who adhere to quality standards.

Attend Trade Shows

Trade shows such as the Canton Fair, ISPO, or FIBO provide excellent opportunities to connect with manufacturers directly. These expos allow you to physically check samples and evaluate materials, which can help you gauge the quality of the products before making any purchasing decisions.

Request Samples

Always request samples from potential manufacturers. Pay attention to the thickness tolerance, tensile strength, odor, and surface grip of the mats. This hands-on evaluation will give you a clearer picture of what to expect in terms of quality and performance.

Audit Capacity

Inquire about the manufacturer’s production capacity. Ask for details such as daily output, the type of machinery they use, and references from major clients. This will help you assess whether the manufacturer can meet your order volume consistently.

Lock in a Contract

Once you select a manufacturer, it’s vital to lock in a contract. This agreement should cover aspects like lead time, defect rate thresholds, penalty clauses, intellectual property (IP) protection, and payment terms. A well-defined contract helps mitigate risks and ensures clarity in your business relationship.

Recommended FDM Yoga mat manufacturers:

- Known for their eco-friendly materials and quick turnaround times.

- Offers extensive custom options and competitive pricing.

- Specializes in high-performance mats suitable for various yoga styles.

- You can negotiate the minimum order quantity with them.

Summary of Why Factory Direct Supply Is More Cost-Effective

Factory direct purchasing isn’t just about cutting costs—it’s about gaining control. By working hand-in-hand with the source, you unlock tailored products, agile lead times, and a supply chain edge your competitors can’t easily replicate. Ready to boost margins on your next yoga-mat order? Start vetting manufacturers today and see how far factory direct savings can stretch your budget.